greatly enhance safety at the race. All of this is from an organization that

has virtually no fire trucks or a full-time staff!

greatly enhance safety at the race. All of this is from an organization that

has virtually no fire trucks or a full-time staff!On Your Marks, Get Set, GO!!

Fire Safety at the Indianapolis 500

(From Firehouse Magazine, October, 1993)

It's

Race Day at the 1993 Indianapolis 500, and one of the largest crowds in Indy

500 history is on hand to watch one of the safest Indy races yet - thanks partly

to slower qualifying speeds and changes in the track design. However, the efforts

of an extensive, dedicated and highly-qualified fire safety and EMS crew that

represents the state-of-the-art in fire safety today also greatly enhance safety at the race. All of this is from an organization that

has virtually no fire trucks or a full-time staff!

greatly enhance safety at the race. All of this is from an organization that

has virtually no fire trucks or a full-time staff!

This is due to the fact that the Indianapolis 500 is an event, and is treated as such by the administrators of the Indianapolis Motor Speedway. When there is no activity at the track, there is no need for a fire crew. So, for obvious budgetary reasons, there is no full-time fire department at the track. During these times, the fire protection of the racetrack facilities is maintained by the Speedway, Indiana Fire Department, located less than a mile away. During the month of May, however, fire protection becomes a whole different story.

The Indianapolis 500 is known colloquially as "the greatest spectacle in racing," and anyone who has been there would find it hard to disagree. For the racing teams, it is the "creme de la creme" of races. In order to get the most preparation possible, the racing tears start arriving the first week in May. When the racing teams arrive, the need for fire safety begins, and the fire safety workers are called in.

The firefighters that make up the fire safety crew are generally members of neighboring fire departments, including the Speedway, Indiana and City of Indianapolis Fire Departments. Many of these firefighters also work at the Indianapolis Raceway Park. For the bulk of the month, the track keeps a crew of roughly 60 firefighters on hand under the supervision of United States Auto Club (USAC) Track Safety Coordinator Jack Gilmore. In addition to standing by while the cars are out practicing on the track, their duties include readying all of the equipment that will be used during Carburation and Race Days.

The fire apparatus that is used at the track during May is not purchased, but is in fact donated by the manufacturers for use during the month. This year, Chevrolet donated 14 2500-series pickups for use during the race. After the race is over, the trucks go to dealers throughout the country to be sold as "Indy Specials." There is a similar arrangement with a Class-A pumper that is kept at the pit lane exit; this year a Scorpion body on a Nissan chassis was used.

While the pickup

trucks are the "front line" of fire/EMS safety at the track, what

is not generally known is that they are divided into two categories: "fire

truck" and "safety truck."  While

their duties overlap, each is designed to perform a different function. There

are 12 fire trucks positioned at key points around the track (see diagram)

and two safety trucks. One safety truck is positioned at the infield center

of each short straight between turns 1 and 2, and 3 and 4, respectively.

While

their duties overlap, each is designed to perform a different function. There

are 12 fire trucks positioned at key points around the track (see diagram)

and two safety trucks. One safety truck is positioned at the infield center

of each short straight between turns 1 and 2, and 3 and 4, respectively.

Despite the large amount of expense and high technology that goes into the Indy cars and the Indy 500, the first choice - by far - of fire attack methods on the track is, surprisingly, a simple pressurized-water extinguisher! This is due to the fact that the Indy cars run on Methanol, which is a clear, colorless, odorless alcohol derivative that is 100% water soluble. It also burns extremely hot - from 750 to 2000 degrees Fahrenheit. Because it is so pure, it burns with no smoke and no visible flame. This makes for an interesting scenario; members of the fire safety crews are trained to look for "heat waves," similar to those you would see coming off of the roof of a car on a hot day, to distinguish where the seat of the fire is. Indeed, the story is told of a firefighter who, wearing full turnout gear, rushed to the aid of a driver, only to look down and see his shoelaces on fire - he was standing in the seat of the invisible flames!

The fire trucks at Indy usually carry two pressurized water extinguishers, plus two CO2 and two dry chemical (Purple K) extinguishers. In addition, there is a 150 lb. dry chemical extinguisher with a hose reel mounted in the pickup bed, alongside an equal-sized CO2 extinguisher with a hose reel. Despite the seeming emphasis on dry chemical and CO2, water still remains the preferred choice for these additional reasons: very often the engine block and magnesium-alloy wheels of the Indy cars are extremely hot, even in a non-fire scenario, and the use of CO2 with its extremely low temperature may cause the engine block to crack and/or the wheels to explode. While dry chemical may be effective, it's been said trackside that if a firefighter gets any dry chemical on the motor he'd better be a fast runner...or at least as fast as the pit crew of the car whose motor he destroys!

The fire trucks

usually carry a crew of four, consisting of a driver, a front passenger and

two firefighters in the rear, at the ready with extinguisher nozzles.

The

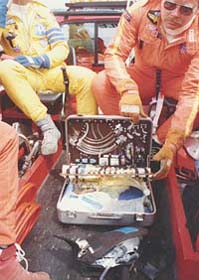

two safety trucks on the track perform more of a first response/rescue/EMS function.

In addition to fire extinguishers, they are equipped with a "jaws"

tool and a pneumatic speed cutter, as well as EMS essentials such as a Med Kit,

a defibrillator and specially-designed narrow backboards for use with the Indy

cars. The safety trucks usually carry a crew of six, made up of the driver (who

is usually the crew chief), a front passenger, a paramedic seated directly behind

and with his back to the driver, a utility man, a point man and a pace car point

man.

The

two safety trucks on the track perform more of a first response/rescue/EMS function.

In addition to fire extinguishers, they are equipped with a "jaws"

tool and a pneumatic speed cutter, as well as EMS essentials such as a Med Kit,

a defibrillator and specially-designed narrow backboards for use with the Indy

cars. The safety trucks usually carry a crew of six, made up of the driver (who

is usually the crew chief), a front passenger, a paramedic seated directly behind

and with his back to the driver, a utility man, a point man and a pace car point

man.

The Class-A pumper, which is positioned at the end of pit row, is usually more for insurance than for anything else. One fire crew member recalls only once in 22 years - when Salt Walther crashed - that the pumper had to come out onto the track.

There is also

ample and thorough fire safety in the pit area. The Methanol storage tanks in

each driver's pit hold 275 gallons, so this is actually where there is the most

danger of fire, and emphasis is placed upon fire protection there. There is

a charged three-inch water supply line that runs the length of the pits, into

16 hole reels spaced one per two pits.

Extinguishers of all types are also present. In the race cars themselves, there is a "T" handle located above the left shoulder of the driver that, when pulled, kills all electrical connections and discharges a 2-1/2 lb. CO2 extinguisher into both the cockpit and engine compartments.

As the month of May draws to a close and Race Day draws near, activity at the track increases. On Race Day, Class-A pumpers and their crews from up to 10 neighboring fire departments are called in to provide fire protection in the infield and outside gate areas. Additional fire crew personnel arrive for the race. On the track when the race begins are the crews of 12 fire trucks and two safety trucks, additional "bottle" (extinguisher) men in turns 1, 3 and 4, two men per pit (there are 33 pits) plus one on each of 16 hoselines, plus 18 "floaters" for a total of roughly 100 firefighters in the pit area alone. All told, at the start of the race, there are over 205 fire crew personnel on the scene.

During the race,

there is an extensive network of communications, so that information about what's

happening on the track is known simultaneously around the track. USAC, the sanctioning

body of the Indianapolis 500, maintains 12 observation stations around the track

that are in constant two-way communication via a "land-line" with

Race Control in the tower along the main straightaway.  These

communications are monitored by both Jack Gilmore, the track safety coordinator,

and all of the drivers of the fire and safety trucks positioned around the track.

The track safety coordinator is in constant two-way communication with all of

the fire and safety trucks on the track fire frequency. In addition to this,

one member of each truck monitors a separate radio frequency used by the pace

car, so that in the event the pace car comes out onto the track, instructions

can be given to the pace car driver as to where to most safely lead the cars

around an accident or debris.

These

communications are monitored by both Jack Gilmore, the track safety coordinator,

and all of the drivers of the fire and safety trucks positioned around the track.

The track safety coordinator is in constant two-way communication with all of

the fire and safety trucks on the track fire frequency. In addition to this,

one member of each truck monitors a separate radio frequency used by the pace

car, so that in the event the pace car comes out onto the track, instructions

can be given to the pace car driver as to where to most safely lead the cars

around an accident or debris.

If a crash occurs,

it is usually picked up by the USAC spotters even before it fully happens. A

cry of "Yellow! Yellow! Yellow!" will be transmitted. At this point,

both safety trucks will respond onto the track, often before the car or cars

involved have come to a complete stop. En route, they are filled in via radio

about the nature, location and severity of the crash. The closest fire trucks

are then dispatched to the scene.

The primary emphasis on the track, as it is around any motor vehicle accident, is on the safety of the emergency personnel and of the other race drivers not involved in the incident. The crew members of both fire and safety trucks will usually have specific assignments. When arriving on the scene, the driver, passenger and paramedic from the safety truck will go directly to assist the race car driver. The utility man will stand by with the "jaws" if needed, while the point man and the pace car point man work to direct the flow of race traffic around the scene safely, while picking up debris. The crew of the fire truck, if not needed for fire suppression, also helps with this.

The Indianapolis Motor Speedway F.D. is considered by the State of Indiana to be a "Special Category Fire Department," in that it exists only during the month of May, or during events at the track. The training required to work at the speedway has become more formalized as the technology that goes into the Indy cars has increased. Due to requests for this specialized form of rescue training, Track Safety Coordinator Gilmore has initiated a Motor Sports Emergency Services Course given at the speedway, that is soon to be certified by the State of Indiana. NASCAR will be coming to Indy in 1994. An experienced, trained and dedicated fire crew will be there and ready.